BOW THRUSTER

I thought it was a toyish addition to the boat and resisted adding it.

The thrill of docking in a slip with a single screw boat, with a cross wind of 20 knots and current athwartship, watching in sweaty palmed composed panick asthe crew is unable to hold the bow. Wind loads are heavy on a 50 foot boat and this one is less than some more modern designs.

I took the plunge, after talking to many skippers. Unnecessary for most docking situations, a thruster is like extra help against skipper and crew mix ups. And that does not even include the dock hands who seem to be trained only in self professed expertise in all matters vessel handling.

I came to be known in the yard as the crazy guy who installed his thruster. Trust me, it was not without fear and ample planning time was taken.

I must say it was audacious to cut the hull, a mistake would have been costly in time and effort. Yet, the work was straight forward fiberglassing with epoxy, once you got over the idea of making two 8 inch giant holes at the bow which could sink your boat in 5 minutes. It took a few weekends to get this done, and I will explain how.The first challenge is that there was a holding tank, and a structural bulkhead which extended slightly above the waterline, in the area where the tunnel should go. So the first step was a new holding tank of fiberglass epoxy, which is compatible with acids, fomaldehyde, sea water, etc. ( I am amazed actually that some manufacturers like Island Packet use aluminum for holding tanks).

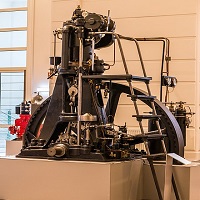

The Sidepower SE100 is sufficient, tp 20-25 knot breezes. After that, you hope your skills and timing is perfect and must decide if you shoud anchor and wait.

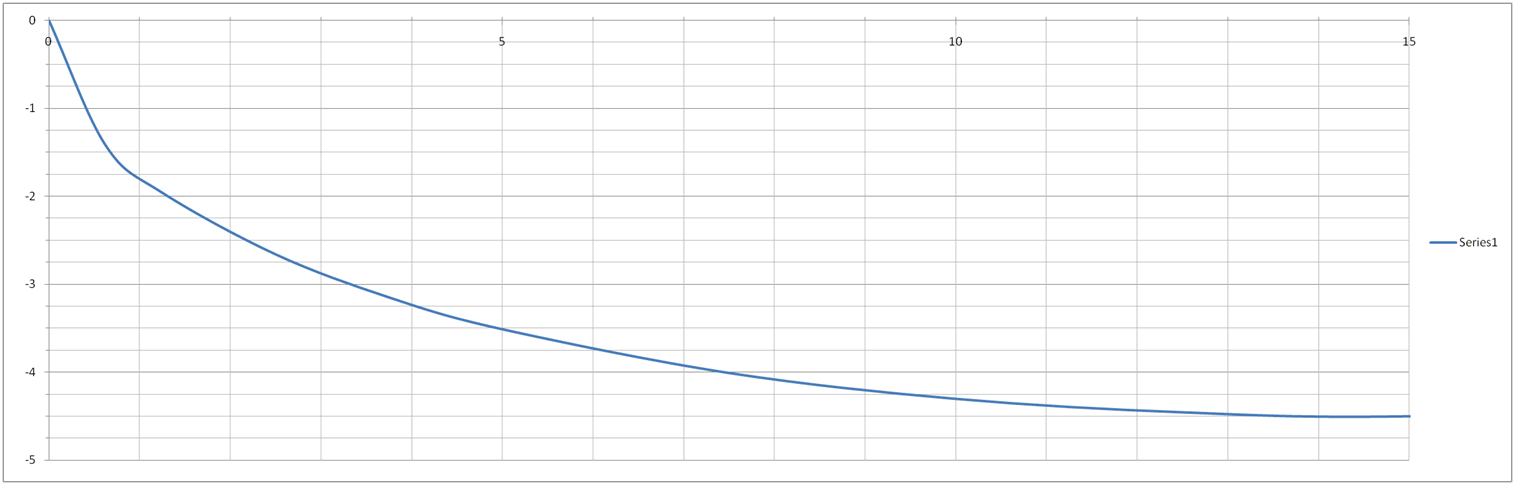

For power, most thrusters use a deicated battery bank, in this case two would be typically used. This allows a 24 V thruster, and the batteries are replenished with a DC/DC charger feeding off the house bank, or AC, or the engine. The consequence is a high current demand on two batteries, and a deep and fast depletion of charge. I decided to tie the thruster to the house bank, and this allows normal charging of all batteries at the same time, but required a heavy wire bus ( 3/0 or 4/0) from the aft bank to the forwrad thruster batteries. And this also allowed me to dedicate three batteries to the thruster, so all the batteries suffer equal stresses. A cutoff switch is in the area of the thruster. It is switched off whenever we dive the bottom. The wire bus is fused, and each battery in the house bank ( 8 of them) is individually fused.