Engine Project

At 6300 hours, Frog's Leap's power plant is not young. It was probably not the first engine in this boat either, though this is hard to tell. The engine shop owner commented the engine was in good shape for its age, but its age is why I did the rebuild. This started with smoke at high load, and in reverse while docking. I figured that the injectors were in need of another round of rebuild and purchased new ones in Martinique in 2023. This did not cure the problem. A mechanic was summoned for an opinion and sea trial prior to hauling our for the summer of 2023 in Grenada. It turns out his diagnostic was spot on, we found out later. FOr one, he said the turbo was probably not the source of the oil. He quickly isolated the problem to blow by, suggesting cylinder rings were worn.

My next step was to take the turbo off and also do a compression test on the engine. A note on this: If you must do a compression test, do not remove pressurized oil components. The clean up of the engine bilge was wasted effort]. Within the coing week we had performed a compression test and found that one cylinder was off. [A note on this, most mechanics label Cylinders 1-4 from the front of the engine back, but Yanmar and Wartsila have the reverse convention: Cylinder one is at the flywheel side of the engine for those manufacturers ]. The results showed mediocre compression on three cylidners, and significantly less on others. 420 / 360 dry and much higher in wet test. Decisions on numbers like this are difficult: The engine was not bad enough to assure the need for a rebuiding, but it was bad enough that continued degradation and a rebuild was guaranteed down the road. At this point, one makes a decision based more on the philosophy of how things should be maintained, versus the funcionality of the engine. Plenty of cruisers and fisherment have no problem going around with smoky engines that give our a small amount of oil, barely enough for a sheet as you clear the exhaust with high RPM. The proper engineering approach, however, was to rebuild the engine.

Rebuild vs New?

The decision to rebuild vs putting in a new engine depends on financials and willingness to throw money at a problem, and also the willingness to adopt new technology. You cannot buy a replacement engine that is mechanically injected any more, at least not in the USA. Electronic common rail injection engines are better, quieter, more fuel efficient, than the generation of engines that I have. Their Achilles heel is lightning. If you are unlucky enough to get struck and lose your engine control module, you will be assured a tow, or a very long passage if winds die. And I was told that obtaining a spare controller is next to impossible. But regardless, ECM software will be the reliability weakness path. One report, an engine exceeded its heel angle and the ECM sht down. Another report, a loose ground wire caused a shut down. That would seem innocuous, until you consider that a technician with a computer had to reset the ECM to get the engine started again. What's good for a tractor is not acceptable in the marine world. Imagine the domino effect on a 10 day passage if this happens offshore. Back to the question of New vs rebuild, of course, it depends. I did not change the main crankshaft bearings or have to bore the cylinder, so the total parts and shop time were less than $6,000. I f I had to comission the shop to do all the work, the chances are that the engine cost would be prohibitive. THe price / value ratio favors a new engine, because 1) the shop time could be $10K to $12K, 2) The shops do not want to take on warranty issues, but a new engine has warranty coverage. 3) The parts for a full rebuild are set very high by Yanmar, making sure new engines are attractive. FOr my DYI approach the engine rebuild was affordable, avoided the need to redo accessories, engine beds, buy a new panel, repurchase spares in the form of pumps, impellers, and starter motors, which Yanmar did not create any compatibility for from one model to the next. All this would bump costs up well into the mid to high 20s.

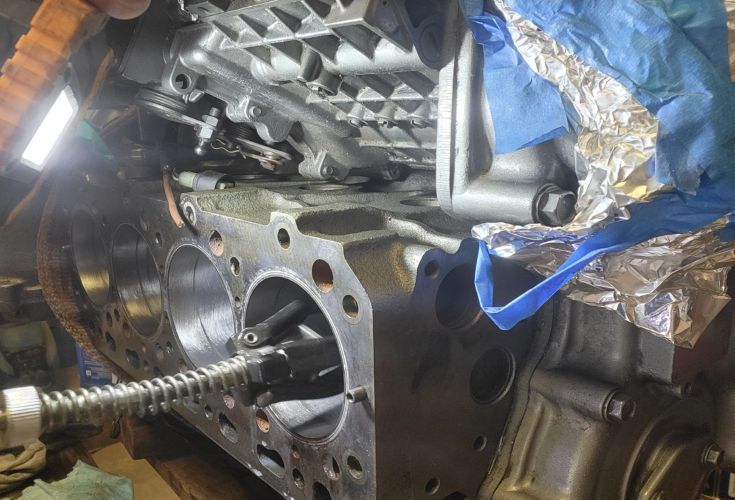

Is it still good enough to rebuild? Even with the considerations above pointing to a rebuild, the question remained for me as to thes state of the cylinders. A visual inspection indicated things were pretty good, but what about measurements? Palm Tree Marine had no capability to measure cylinder bores and head flatness [ no one in Grenada had such tools and in my yard the mechanic did not even have a compression tester]. Palm Tree, however, knew people and found someone who had such tools, was a retired airline pilot for British Air, and gladly came to help me with measurements for a very reasonable fee. Once assured the engine was within the wear limit dictated by Yanmar, I decided to proceed with the parts ordering. The parts took two weeks, which proved that Island time is the same as USA time. The wear limit is 82.06mm and we measured 82.04 to 82.05 range in the worst spots. The head was flat within 0.001 inches. ALl in all, this engine was in great shape other than the compression issue.

A false start on the rebuild job

The engine work did not start out a planned: before contracting Pam Tree Marine, I found another mechanic who thought he could help me with the rebuild. Probably both of us were wishing for it to work without being realistic about the situation. I eventually pulled the engine when it became clear that the engine was not in some proper shop and this was confirmed when cylinders dimensions were made up or at the very least made no engineeing sense relative to spec ( the cylninders had more steel than spec despite wear). I am including this to say that in the Islands, you need to be cautious about the capabilities and tooling available. For precision work, tools and machinery lack. There are extremely talented people but their trade is quick fix, not ponderate decisions. This is the marine industry in general for consumer repairs in the US, but the shortcuts take a different magnitude in the islands. Be present and be knowledgeable if you have work done there.

Keep it clean

In the end, a clean shop makes a whole lot of difference. Engines don't like wind blown dust very much. In order to adhere to meticulous disassembly and reassembly, you need bench space. Pictons have to go back in the same bores, and new rings lapped onto the valve seats will need to be reassembled in the same order. You also cannot swap connecting rod bearing caps. All this means a clean shop, protected from the elements, and with at least 8 feet of bech space and an engine stand. Palm Tree Marine was probably the only place in Grenada where I would consider internal engine work.

Many people will sing the prowess of the mechanics or electricians or welders that they had work on their boat. I believe the skills are often excellent, and you need to assess whether the facilities as well as the skills atch then needs. A great oil change mechanic is not the same as a great engine troubleshooter or an engine rebuilder. At Palm Tree Marine, there were 3 experts, two other very capable people who would need minimal guidance. Others were assigned simpler tasks and things worked well as a result. Most customers are not equipped to assess the capabilities, so I leave it with you that a recommendation is only as good as the knowledge of the person making it and the match to your need.

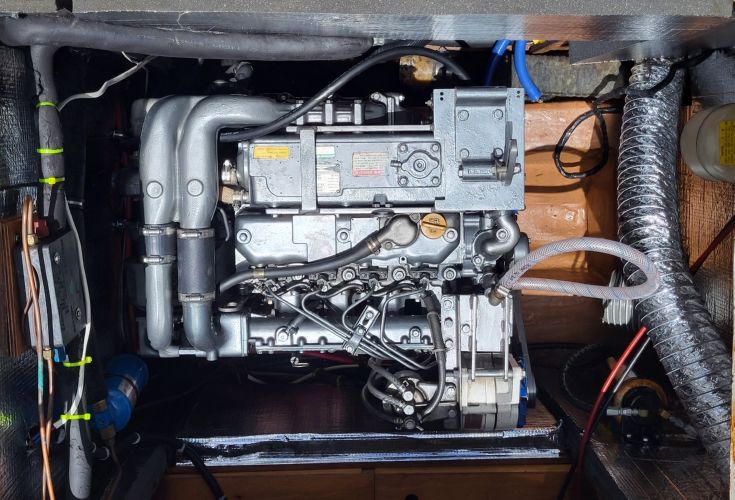

Tearing apart and rebuilding We sat for two or more weeks waiting for parts. I was able to reline the engine roo with insulation foam during that time. Two inch foam with a heavy polymer weighted sheet to absorb sound was placed in the engine compartment and glued in place. Much of the work was difficult because of the heat and humidity in grenada, and I had to frequently close the lid on the engine floor due to rain showers. But the result was very satisfactory, I also resecured all wiring and rerouted some.

If you hang around and are lucky enough that real professionals use you as a pair of hands in their shop, you learn a load of tricks, proper orientation of the cylinders, labeling parts for reassembly, sanding down the cylinder head gasket with WD40 to clean residual gasket pieces after scraping, etc. In a sense, I got a free mechanics course, saved on labor by doing my work, and helped the shop upgrade a couple of tools. It was a win win. My advice in general on the rebuilding: Be meticulous, follow all the torque specs, have lots of ziploc bags to place parts in, and label everything. I estimate 150 parts for medium rebuild like mine, including gaskets, hoses, and nuts and bolts. Each has a place, and careful organization is paramount. Taking the time to stay organized is well worth it in avoiding problems.

After the rebuild, I went and bought some heater hose and we set up the cooling system, filled the crankase with oil, connected a temporary fuel tank. The engine needed priming, and I found a return and a feed swapped. After that was fixed, it started right up. I am returning in Oct to send the injection pump to the states for a full rebuild. This is the last remaining investment into the old workhorse for a while.

Diesel Principles

Diesel, a German inventor, realized that sufficiently high temperatures could be obtained to reach the ignition point of an air and fuel mixture, without a spark. Typically theseare called Compression Ignited Engines as a result. Physics saty the same, but the engineering evolved tremendously over the years, and there are two companies proposing new engine designs. https://www.liquidpiston.com/ is a startup with a completely new rotating chamber design that they claim will solve the reliability problem of wankels and rotary engines. The amount of energy output per volume and per weight unit is amazing. Cummins,

https://www.cummins.com/news/releases/2021/07/30/us-army-awards-cummins-inc-87m-contract-deliver-advanced-combat-engine

is a well established engine maker for industrial and transportation sectors, as well as marine, and has received very large engineering funds to design the next tank engine, which claims a much higher efficiencyand compactness as well. The remarkable thing is, that in a field where you would expect innovation to be replaced by a steady state, there are continued investments disrupting ideas. I for one would be delighted to see a 100HP in a fraction of the weight and volume of my current power plant, especially if the efficiency is higher.

Diesel engines are, today, heavy, the weight driven by reliability and the high compression ratios.

We can hope for this to change.

Frog's Leap 4JH2-HTE

Back to present reality, Frog's Leap's engine is a Yanmar, one of the leading brands.Perkins, Volvo, Nanni, Kubota operate in this power range as well, and in the marine sector. Marine isa relatively niche sector, a derivative of the tractor and small construction equipment engine space. At 76 HP the engine is ony 1.8 liters in displacement, which means it is turbo boosted. The benefit is a smaller lighter engine than a naturally aspirated one, the drawback is that turbo needs more maintenance and is more prone to problems. In Frog's Leap's case, the engine is approximately 500 pounds lighter with the turbo than a competitor's same horsepower motor. In terms of cruising boats, that's the whole scuba equipment, extra chain, and the sewing machine that are onboard ( and may be none of this should be onboard). So we are already benefiting from improvements in technology for small marine engines, which scaled down from the industrial world.

Frog's Leap's Turbo'

Because the amount of turbo boost the engine is intercooled: The turbo output air is circulated in a heat exchanger to cool it, using seawater, much the same as a heat exchanger for lubrication oil or one for the engine fresh water system, except the intercooler uses fins, not just tubing, more like a radiator design. Turbos have one disadvantage, a significant reliability longevity gap to the rest of the engine, due to the very high rotational speed.

Simple but complex

There is more to a turbo than its simple principle. Materials have to withstand high temperatures of the exhaust, spin at 100,000 rpm in perfect balance, and keep oil within the oil system, without burning it out of the engine. They are expensive ( this one is >$2000) and warrant some basic care. Running dry of oil is one of the top reasons for bearing failures on turbos. Another top reason for damage is improper cool down.

The Turbo on Frog's Leap is probably spinning in the 100,000 RMP range. Considering one side is subjected to exhaust manifold gases one can understand how its lifespan is in the 3000 hours on a typical use sailboat engine. Most of the time, the bearing surfaces develops wear and this causes problem. Sometimes catastrophic failures occur.

Cooling Down - Critical

One key component of Turbo failure is the method for cooling. Many skippers forget that the Turbo temperatures are high after strong demand, and manufacturers often recommend a cool down period ( 3 to 5 minutes) to get the turbo to lower temperatures. On the other hand, idling causes issues, as the motor will build soot in the sylinders, and cylinders prefer higher temperatures.I like to stop the engine right after the turbo cool down, whenever possible. RPM for cruising is also important for the engine.

Cruising Speed - Fuel or Glazing Choice

I think 2600 RPM to 2800 RPM is the right speed for ensuring soot does not build up. The idea of blowing out the cylinders at full RPM for 5 to 10 minues every hour is appealing, and porfessed by many. If you think about it though, the cylinders will go back to lower teperature within 4 to 5 minutes of returning to slow speed, and this will allow a good 45 minutes for the engine to soot up and have carbon glazing the cylinder walls, a major compression loss then takes place. I have read about one captain who kept his 4 cylinder motor, more or less equivalent to mine, at 1800 RPM for long passages, replaced the engine with a brand new one and found a year later that the new engine had the same problems: Smoke, oil, low compression, etc.

Soot Collection

Keeping the RPM high enough to ensure no build up of Carbon is one way to protect the engine and the turbo. This means burning fuel unfortunately. The other way is to improve on the lubrication system with a soot collection system. On large engines, a centrifuge. On small engines, a bypass 2 micron filter such as this AMSOIL unit.

Idling is an enemy of engine life. These diesels can run forever. That's what they are made for as long as you load them with torque. On a turbo it is not good to run below turbo speed and that's a problem. Turbos don't like to run slow, and they suck fuel when running fast. People tell you the engine is more efficient with turbo on, that is not true in the sense of fuel efficiency, but it may be true in total cost of ownership.

Making the engine last

Having just completeed a rebuild of the engine on the boat, I In addition to the cool down / warm up periods and operating at a high enough temperature to maximize engine life, people will tell you that the engines will run forever if you only have good fuel and change the oil. That is mostly true. But some things are also important, routine maintenance items, which I have learned from some Yanmar mechanics:

- Changing the coolant is critical. The heat exchanger dorrodes over time, and actually removing it aver so often to clean it out is important. Mine was in good shape, thankfully.

- Changing the coolant is critical. The heat exchanger dorrodes over time, and actually removing it aver so often to clean it out is important. Mine was in good shape, thankfully.

- Impellers: That and avoiding overheating. A friend of mine had an impeller failure, and concerned about the narrow channel could not anchor, continued to run the engine for an hour at 1200 rpm and ended up needing a $20K refit. Keep the pumps running. ALong that line, if a pump, most likely the raw water pump, starts dripping one drop of seawater every few minutes, take it out of service and rebuild it, or place the spare in operation immediately. The failure sequence will be more dripping, followed by a failed bearing, and by the time you say "what's that noise" you may be in a more difficult position to change things out.

- Fuel: It goes without saying that clean, water free fuel, it critical. The usual scenario is a boat that sits for two years, and the tanks grow bacteria. The bacteria stay in place until you hit some weather. Loose bacteria clog your filter and you end up on a Jetty. There is a sad story related to this: https://maritime-executive.com/article/video-four-sailors-killed-in-yacht-grounding.

- Fuel again: Water. Cloudy Fuel. Make sure you get fuel from a dispensing business that carries volume, or if they do not, that they are boaters using their own fuel. Above ground tanks, instead of underground tanks, and tanks high enough above storm tides that water won't get in. These are basics but they matter.

- Valves: Some engines have valve rocker adjustments. One sure way to lose engine life is to let that go too long. I have performed regular valve adjustments on my Yanmar and as a result the valves were in decent shape albeit needed to be ground, but I probably could have used the old valves at 6300 hours. A Yanmar should sound like a little sewing machine if all is well.

- Oil: One cannot emphasize oil changes enough. The choice of oil, in my opinion, is that heavy duty diesel oils are great, but after the engine is broken in with that, a synthetic does hel reduce wear. One drawback from Synthetic oils is that they tend to be more prone to slipping past imperfect seals. ANother advice on oil: Get a centrifuge ( if your engine is 100HP or more) or use a bypass filter (for engines up to 150HP). The bypass filter takes 5 to 10% of the engine oil and filters it in a 2 micron mesh. Typical oil filters for an engine like mine are 30 microns. This leaves opportunity for carbon in the oil to remain between oil changes, and the same for abrasive silicafine dust, etc. The use of a bypass filter makes the oil clearer and reduces wear. THey can extend the amount of time between oil changes, into the 700 hour range. The cost of oil maintenance over a lifetime is minute compared to the costs of the engine and installation, especially if you learn to change the oil yourself, which I believe everyone should know.